Frac'ing Introduction

The number 1 online oil and gas marketplace

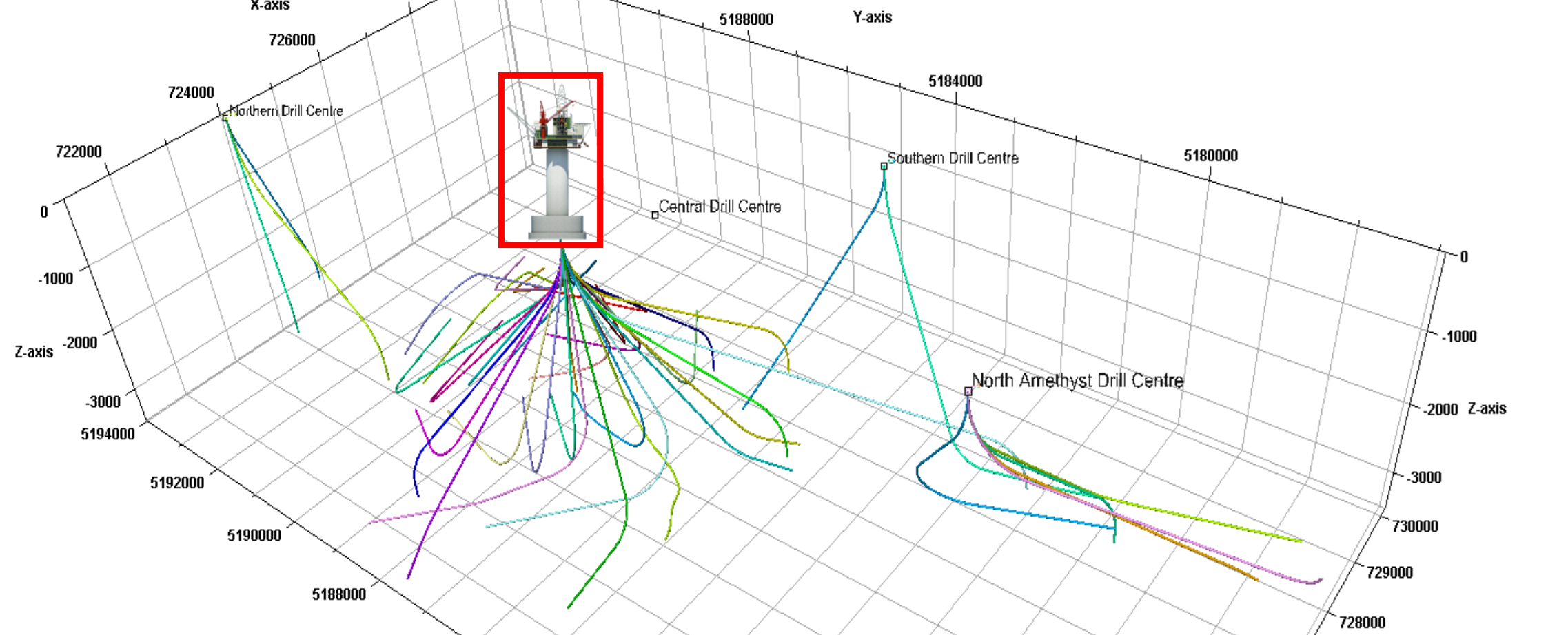

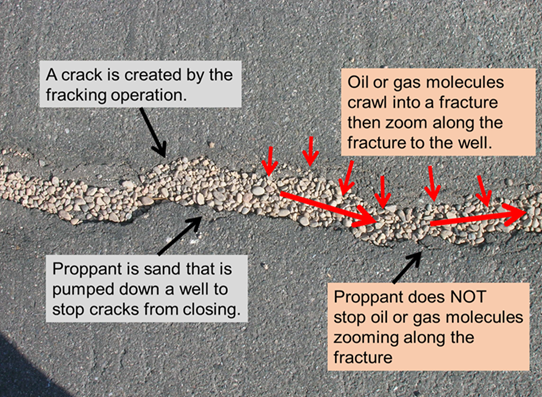

Hydraulic fracturing or frac'ing is an effective means of increasing recovery and production rate from an oil and gas well. This stimulation technique is used to increase the area oil and gas has to flow into a wellbore. Small diameter wells naturally become a choke point for fluid flow and by hydraulically fracturing the rock around the well, a more effective flow path can be opened up.

from Forbes, The Pursuit of Proppant by Ian Palmer

from Forbes, The Pursuit of Proppant by Ian Palmer

Months of planning comes together in minutes

In brittle rocks, like shale, the rock is cracked (slickwater frac'ing), but in a more flexible rock like sandstone, the frac will seal back together when the pressure is removed. This can happen when pressure is bled off from surface, or if the fluid loss to the formation gets high enough that the pressure drops and hence the use of a high viscosity fluid (like the consistency of hair gel) to stop the pressure from dropping and the frac sealing.

"frac jobs have been pumped from supply vessels"

The combination of pumping horsepower, pressure, rate, viscosity and sand density all comes together in a very short timeframe. The variables are adjusted as the rock is fractured, fluid properties adjust, and pumping pressures and rates need to respond. Weeks (and sometimes months) of planning and preparation come down to a frac activity which, in some cases, can go from initiation to tip screen-out in a matter of minutes.