Electric Submersible Pump Design

Tuning the output through design and operation

minutes reading time

Rod Gibbons

Rod Gibbons

Electric Submersible Pumps (ESP's) are a powerful tool for producing high volumes of fluids (oil and/or water) and have been successfully implemented by us in production and injection applications. The ability to apply energy to fluid downhole, and to monitor the application of this energy is a key benefit of ESP technology.

Simplifying the design and operation process is our key focus when it comes to the success of electric submersible pump systems.

Other projects: Geothermal

ESP's in a nutshell

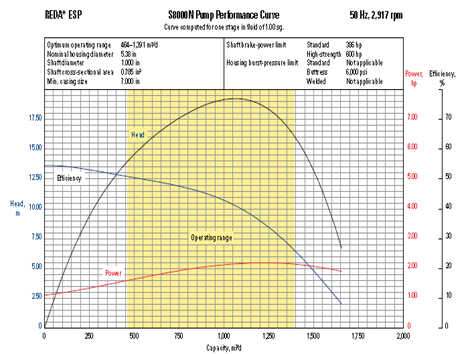

The centrifigual force of the spinning pump stage directs fluid to the outside and the shape of the stage directs the fluid to the intake of the next stage while increasing it's pressure. The required flowrate determines the geometry of the pump stage and the pressure required determines the number of stages.

These two factors then determine the electric motor requirements which then affects the power supply requirements. This concept is simple, but applying this to a downhole environment is not always straightforward - managing the uncertainty associated with oil and water reservoirs and the limitations in the space limitations of well architecture is key in the design of electric submersible pumps.

An elegant design solution also needs to include the installation phase of the ESP system. When designed correctly, ESP systems can last for years, but a critical step in the process is the installation of the electric submersible pump system.

A robust design should include installation considerations (running clearances, banding procedures, electrical connections, surface equipment) to ensure maximizing economic value.

Keep an eye on things

When installed and commissioned, regular monitoring and adjustments will allow the electric submersible pump to operate in it's design envelope. The addition of a variable frequency drive can extend the operating window, but understanding the uncertainty in downhole data is key to maximizing life and value from ESP installations.

"ESP's are a robust technology"

Electric Submersible pumpe can be a great tool for production and injection of reservoir fluids, and understanding the installation and operating conditions that can be expected over the life of the installation is key to a successful install.

A little amount of oversight and monitoring can predict and avoid potential problems before they lead to significant failures. ESP's are a robust downhole technology that can be deployed in many applications, the key being a flexible design and listening to the data during operation.

Homepage >