Choosing when to use slickline or Coiled Tubing

The number 1 online oil and gas marketplace

Well interventions can be highly profitable and there are a number of tools to use. Slickline and coiled tubing are the most commonly used and flexible equipment to diagnose and remediate well issues..

from Schlumberger Oilfield Glossary

from Schlumberger Oilfield Glossary

Slickline and Coiled Tubing are both useful tools

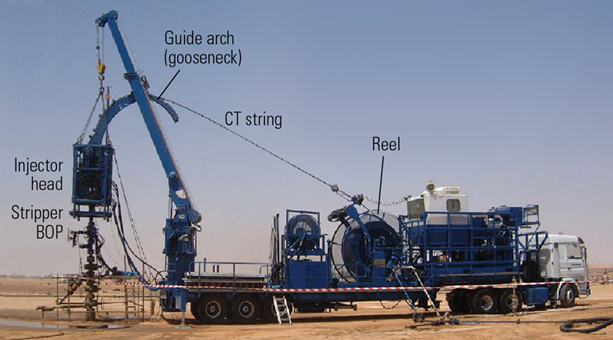

Coiled tubing is also truck or skid mounted for activities in various environments. A crane can be integrated with the unit or mobilized as a separate piece of equipment. Coiled tubing size is referred to as the diameter of the coil which can typically range from 1.25" - 3". Also related for chemical treatments or cleanouts of small diameters a mini-coil or capillary coil is used with diameter around 0.5".

"a strong working relationship... is key"

With it's lightweight toolstrings and low overall string weight, it is much easier to "feel" the well architecture as the weight indicator is more sensitive. The requirement for the weight of the tool string in tension also leads to more accurate depth measurements, in general, than coiled tubing as coiled tubing may spiral when pushed into a well, sometimes providing inaccurate depth measurements.